Plastics in The Age of Coronavirus

Kyle Arsenault, UMass Lowell

The Coronavirus Pandemic has resulted in unprecedented changes in the livelihoods of billions of people around the globe. This blog post will explore the effects that the virus has had on the plastics industry as well as the individual consumer. From everyone at Plastics Facts, we hope that you and your families are safe during these times.

How long can COVID-19 live on plastic surfaces?

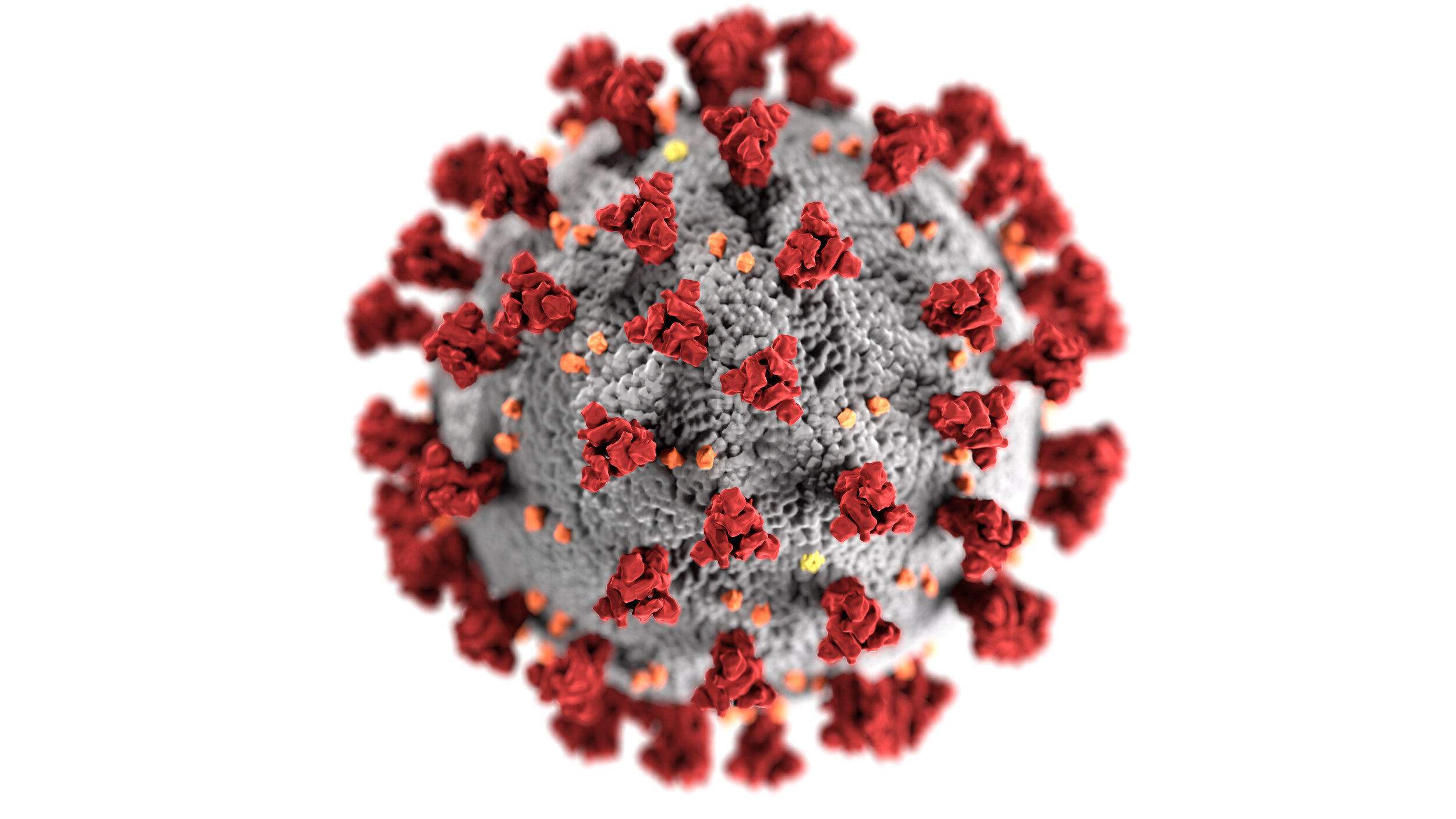

Since this virus has emerged, questions have been raised by the medical community about how long the virus usually lives on different surfaces. The virus is known as a novel-coronavirus, meaning that it is a strain of coronavirus that has not been seen before, the exact characteristics of it are still being researched. The coronavirus is a respiratory-borne disease, meaning that the virus is exchanged through droplets that emerge from the mouth and nose. If a person who is infected with COVID-19 was to cough or sneeze, the droplets that emerge from their mouth or nose could land on a surface or on another person. According to the Mayo Clinic, “Cold and flu virus-laden droplets may remain infectious for several hours, depending on where they fall. Viruses generally remain active longer on stainless steel, plastic, and similar hard surfaces than on fabric and other soft surfaces,” (1).

The Center for Disease Control and Prevention (CDC) has implemented guidelines to help ‘flatten the curve’ and curb the spread of the virus through measures like social distancing, wearing a face mask, and limiting the size of crowds in a given space. These guidelines are meant to stop the exchange of virus-laden droplets from being transferred from one person to the next. John Hopkins University cited a study that was published by The New England Journal of Medicine, that found that the virus can live up to 72 hours on plastic surfaces (2). This finding has led many to question the safety of surfaces or items that may have come in contact with the virus. For example, the grocery store was seen as a location where shoppers could be more easily exposed to the virus, due to a large number of people touching the same items (i.e. food transport workers, grocery store employees, other customers, cashiers, etc.). The public reaction has ranged from doing nothing to the groceries that are brought home to not bringing the groceries into the home for at least 72 hours and wiping down each item with a disinfecting wipe. As of April 12th, 2020, it is suggested that disinfecting groceries is not needed but there are certain measures that can be put in place to shop safely (3).

The Use of Plastics in Medicine

The demand for face masks, personal protective equipment, and viral testing supplies has been unprecedented and has resulted in a shortage of these essential items for governments around the world, including the United States (4). In response, companies have ramped up production of the products they were producing or have converted their entire production line to manufacturing essential equipment/items.

Medical grade masks, including the most common surgical mask and N-95 respirator, are made of plastic. An N95 mask and surgical mask are made from non-woven polypropylene fibers (5). Millions of these masks are being deployed to front-line workers, particularly at hospitals to prevent them from becoming infected or from transmitting the virus. Plastics producers have been ramping up production of raw materials, and medical device suppliers are working to convert the plastic fibers, sheets, and housings into functional protection devices.

In addition to facial masks, plastic face shields are being used to protect medical workers from coming in contact with the virus. These shields are being produced not only by PPE manufacturers but also by people around the world with personal 3d printers. 3d printing has been used during this pandemic to produce everything from parts of ventilators to face shields (7).

As a result of increased demand, the amount of personal protective equipment (PPE) that is being discarded daily is increasing as well. These items are thrown away because they are assumed to have come in contact with the virus and therefore cannot be reused if they were contaminated. Research is being conducted to analyze the efficacy of sterilization methods in killing the COVID-19 virus, in hopes that the supply of PPE does not face shortages (6). The industry will also need to address the safe and proper recycling of used medical equipment in order to deal with the huge amount of waste generated at hospitals and other medical facilities.

The Ban on Plastic Bag Bans

As has been discussed in previous blog posts, many governments around the world have implemented bans on single-use plastics to reduce the amount of waste that is generated from these items. In a stunning reversal of these policies, there has been a shift away from reusable shopping bags to single-use plastic bags due to concerns over COVID-19-contaminated reusable bags. These rapid shifts in attitudes toward single-use plastic create confusion among consumers.

Increased demand for single-use plastic bags has not been to the disadvantage of major companies that produce billions of plastics bags each year. These companies are currently benefitting from increased demand as well as record low oil prices, which lowers the cost of plastic resin. Eric Goldstein of the Natural Resource Defense Council (NRDC) is interested in the long-term effects that this virus will have on our use of single-use plastics, stating that, “While plastic bags are a symbol and only a relatively small piece of the overall problem of single-use plastics, the forecasts are that the amount of plastics that Americans consume will continue to grow significantly,” (8).

Plastics and health industries should start a dialogue on these issues and deliver sound guidance to the public that considers both health and environmental concerns of packaging choices in a given scenario. What the future of single-use plastics may have in store is unknown at this time; however, it is clear the plastics industry needs to continue to adapt, change, and evolve as a result of these circumstances.

References

https://www.mayoclinic.org/diseases-conditions/flu/expert-answers/infectious-disease/faq-20057907

https://hub.jhu.edu/2020/03/20/sars-cov-2-survive-on-surfaces/

https://www.cdc.gov/coronavirus/2019-ncov/hcp/ppe-strategy/face-masks.html

https://www.honeywell.com/en-us/newsroom/news/2020/03/n95-masks-explained

https://news.ucr.edu/articles/2020/04/27/sterilizing-surgical-masks-safer-reuse